Inventory Control Application

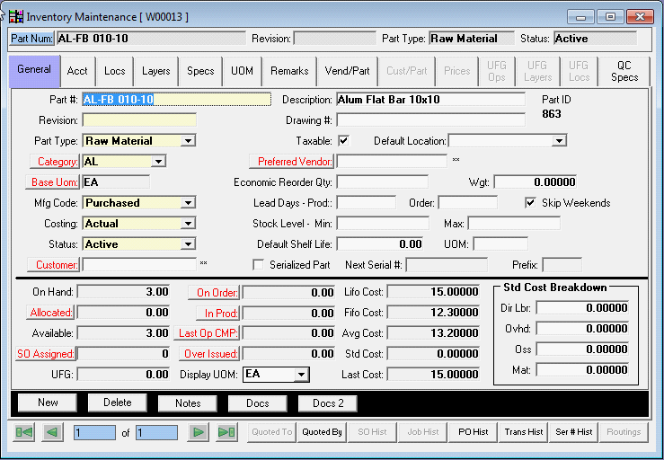

The Inventory Control Application maintains various types of inventory and tracks all inventory transactions. Each inventory item must be a raw material, finished good or tool. We even have an “unfinished goods” file for those finished goods items that have not yet been completed.

You can create as many categories as you want as a way to subdivide your inventory. Each category can be assigned an unlimited number of specification headings. When you enter an inventory item for the first time, you will be prompted to enter the specifications associated with its category (Length, Width, Height…). While the specification headings are common to the category, the specifications themselves are unique to the inventory item.

You have the option to use LIFO, FIFO, AVERAGE, ACTUAL or STANDARD costing for any inventory item. Each of these costs can be broken down into their material, direct labor, indirect labor and outside service components.

You can create as many locations as you want and move material between them. While some companies have one location called SHOP, others have multiple locations specifying the rack and shelf number.

Each material can have an unlimited number of conversion factors giving you the ability to define, as many units of measure as you want for each material. You can buy a material in LBS, issue it in FEET and store it in YARDS

Each time an inventory item is moved (received, issued, shipped….) a transaction is logged which keeps track of its source, destination and beginning balance. These transactions allow you to view your inventory at any point in time.

Key Features:

- Unlimited number of inventory categories.

- Unique specifications for each inventory item.

- LIFO, FIFO, AVERAGE, ACTUAL or STANDARD costing methods.

- Unlimited locations for each inventory item.

- Component cost breakdown.

- Unlimited units of measure for each inventory item.

- Automatic transactions logging when inventory items are moved.

- Tracking of “unfinished goods.”

- Lot number / heat number tracing.