MAIN STEPS & RESULTS

This application is where jobs are created and tracked. It includes programs to enter job routings, post actual employee attendance and labor, maintain outside service transactions and view details of a job’s status.

Routings

Each job contains a routing definition and assignments. A routing definition consists of four components: Operations, Materials, Miscellaneous Items and Employees.

Key Features

- Operation centric – everything is related to either an in house operation or an outside service operation.

- Unlimited operations, materials, miscellaneous items and employees per definition.

- Ability to copy routings from a standard routing, an estimate routing or another job routing using “Same as; Except for” functionality.

- See the Estimate Data Sheet for detailed features of a routing definition.

Job Maintenance

Job assignments allow you to specify why the parts are being made. An assignment can be a sales order, stock or another job. You can have as many assignments as you want specifying the production quantity for each assignment. Assigning a job to a parent job gives you the ability to define complex sub-assemblies. The production quantity of the job is the sum of its’ assignment quantities.

Key Features

- Ability to copy job routings from a standard routing, an estimate routing or another job routing using “Same as; Except for” functionality.

- Unlimited assignments per job.

- Ability to modify assignments at any time in the manufacturing cycle to accommodate changing requirements.

- Estimated costs flow directly from the estimate when copying from an estimate routing.

- The job status screen report allows you to view very detailed information about the status and/or cost of any job. The initial window displays a summary of the job. You can double-click on the summary data to drill down and view the detail behind it.Outside

Service Transactions

Outside service transactions are defined and maintained in this application. This gives you the ability to track the costs and locations of components requiring outside services. Transactions are integrated with the Purchase Order application to facilitate the tracking of outside service receipts and to eliminate duplicate data entry.

Key Features

- Assign an outside service to multiple vendors and/or multiple purchase orders.Unlimited assignments per job.

- Automatic updates of outside service receipts from the Purchase Order application.

- Automatic updates of outside service transaction costs from the Accounts Payable application.

Actual Labor

Actual labor entry allows you to enter the daily time cards from the shop floor. These entries are used to calculate the actual labor cost of the job. You have the ability to break down the labor costs into direct and indirect costs. You can also choose to use the employee’s hourly rate as the direct portion of the labor cost.

Key Features

- Ability to define multiple rates for a given workcenter.

- Breakout a workcenter rate into its’ direct and indirect components.

- Separate rates for setup and production.

- Ability to use actual employee’s rate as the direct portion of the workcenter rate.

- Use a “jobs factor” to amortize an employee’s time across multiple jobs.

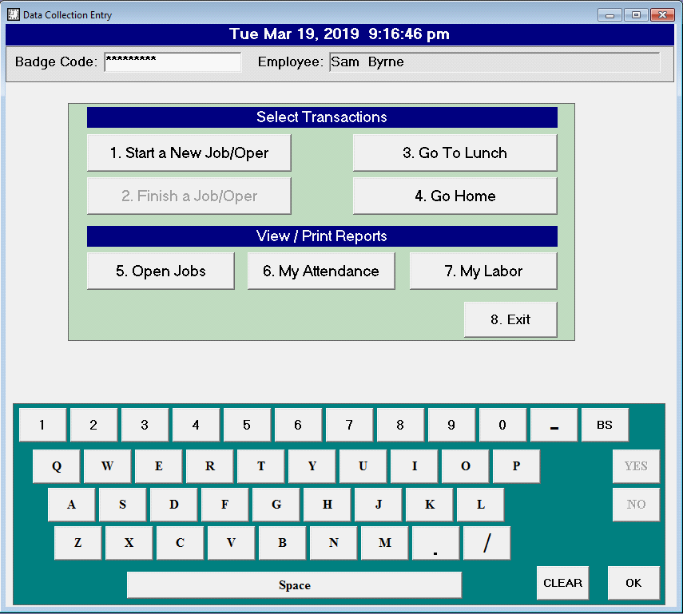

- Design facilitates the integration of shop floor data collection terminals for real-time operation tracking.